Both Dutch and foreign investors are increasingly investing in greenhouse horticulture in the Greater Rotterdam – The Hague area and in particular suppliers to the sector are attracting strong investment. The investment in knowledge-intensive horticultural suppliers quadrupled during the latter half of the seven-year period 2015-2022 due to the robust international growth of greenhouse horticulture, readily available capital in the market and the sector’s multiplier effect. Based on a quick scan, InnovationQuarter, Westland and Lansingerland municipalities and Buck Consultants International (BCI) believe this trend will continue for the foreseeable future.

Strong investment in knowledge-intensive horticultural suppliers

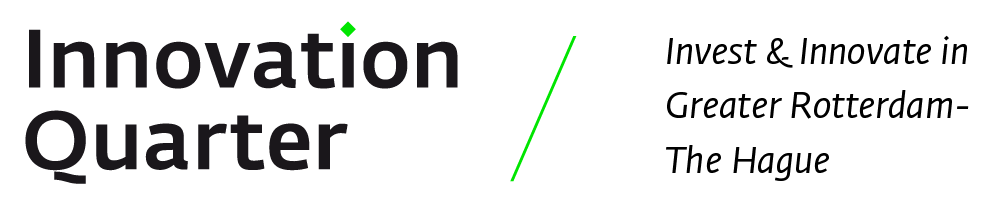

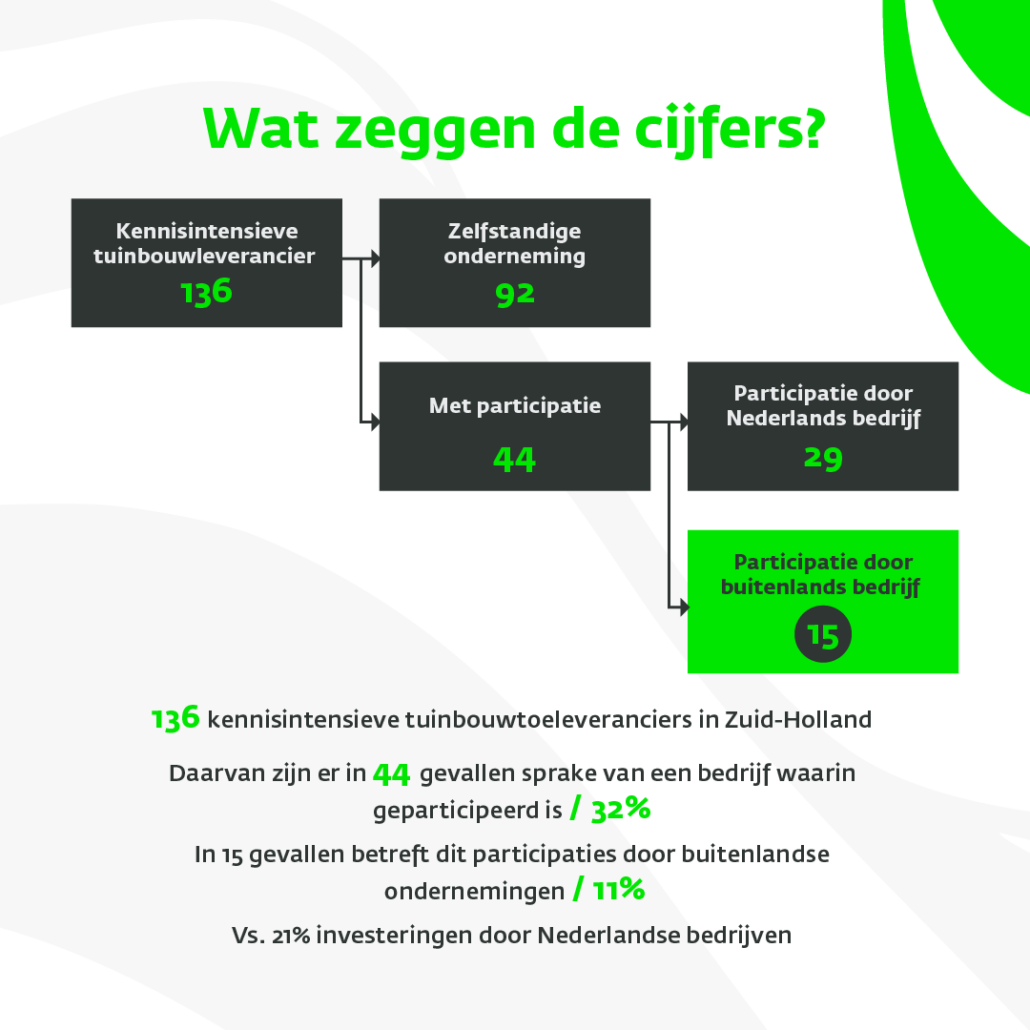

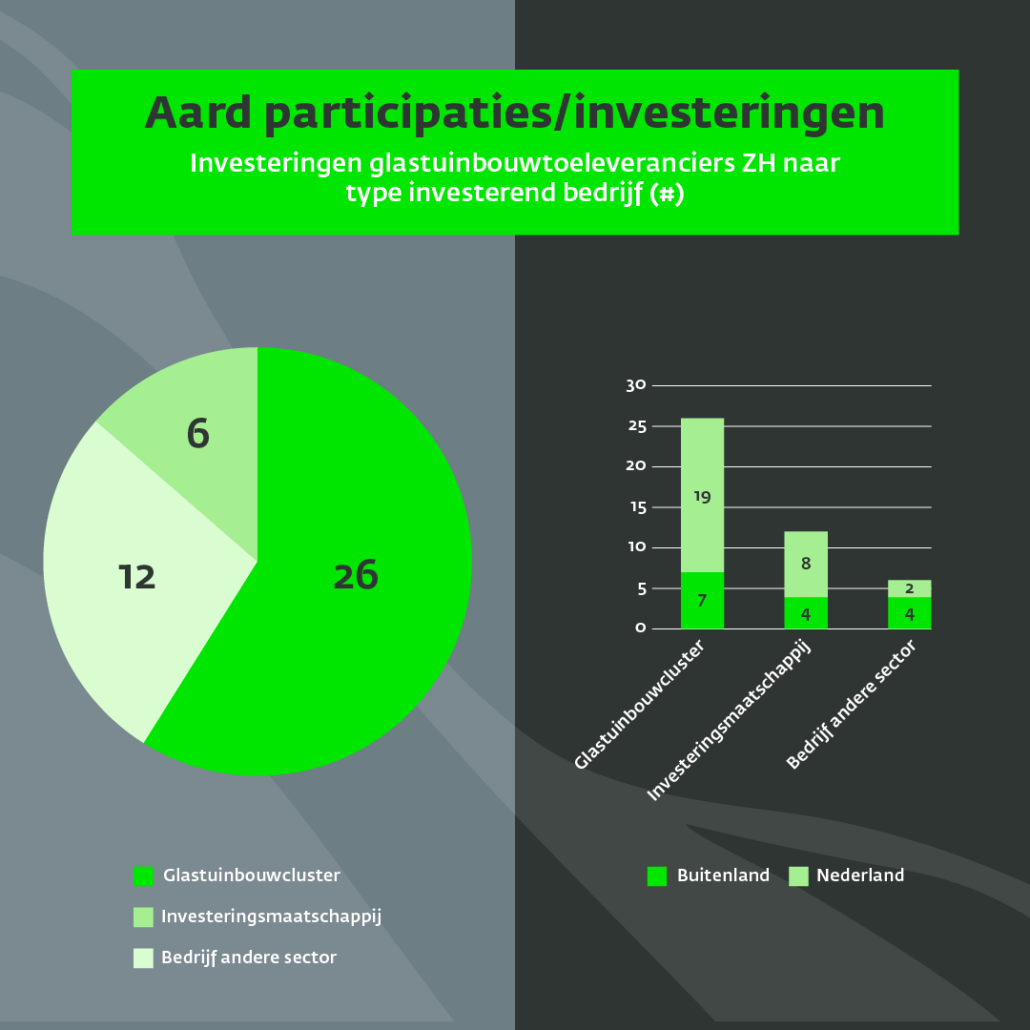

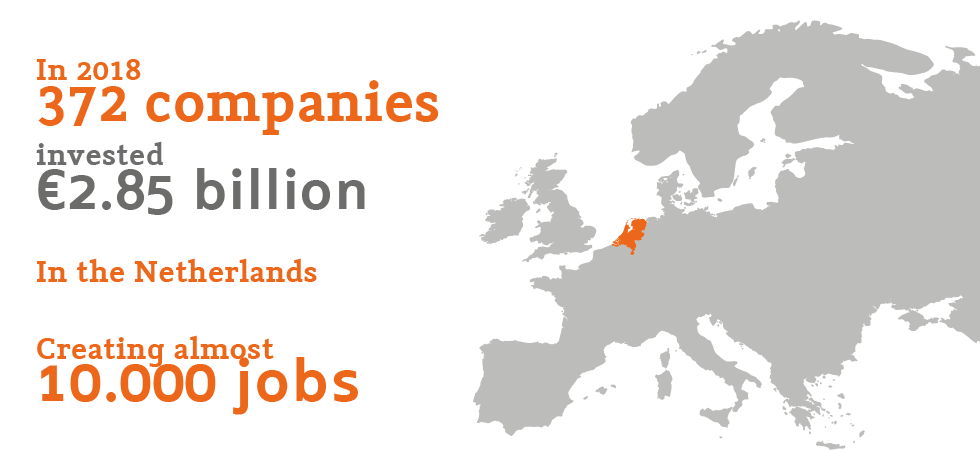

Although Dutch companies outnumber overseas investors by two to one when it comes to investments, the quick scan primarily focused on foreign capital participation in knowledge-intensive businesses in the horticultural supply chain. The analysis concentrated on breeding, greenhouse construction and cultivation and climate systems rather than growers, logistics service providers, wholesalers and packagers. Between 2019 and 2022, some 44 of the 136 knowledge-intensive horticultural suppliers surveyed in the Greater Rotterdam – The Hague area attracted investments. This represents a fourfold increase compared to the 2015-2019 period. Most capital participations are from companies active in the horticultural cluster, followed by investment groups and businesses operating in other sectors.

Many greenhouse suppliers regard investment as a logical step as part of a strategy to boost opportunities in product-market combinations, technological development and professionalisation. Other motives include transfer of ownership and finances.

Alderman Pieter Varekamp of the Municipality of Westland, which is part of the Greater Rotterdam – The Hague area: “The survey shows that investors recognise the value, strength and considerable potential of our greenhouse horticulture cluster. Businesses in the Westland region are actively seeking external partners and we expect the growth in investment to persist. The scan also shows that our region is a frontrunner in greenhouse innovation. We will continue to create an attractive business climate and strengthen the greenhouse horticultural sector, with Westland as the beating heart of the Greenport.”

Regional government and accelerators

The quick scan affords local authorities and regional agencies valuable insights into how this trend can help build towards a strong cluster with a primary focus on preserving the regional greenhouse horticulture area, stimulating an innovative leadership culture and encouraging talent development.

Chris van Voorden, head of Internationalisation at InnovationQuarter: “For many years, InnovationQuarter has been actively cultivating an attractive business climate, including supporting foreign businesses in sectors like horticulture to settle in our region. International companies significantly contribute to employment and innovation investment and it is vital to stay connected with these corporations in the region, which we achieve through the Investor Relations programme. The programme also identifies important developments, not least key trends such as this one.”

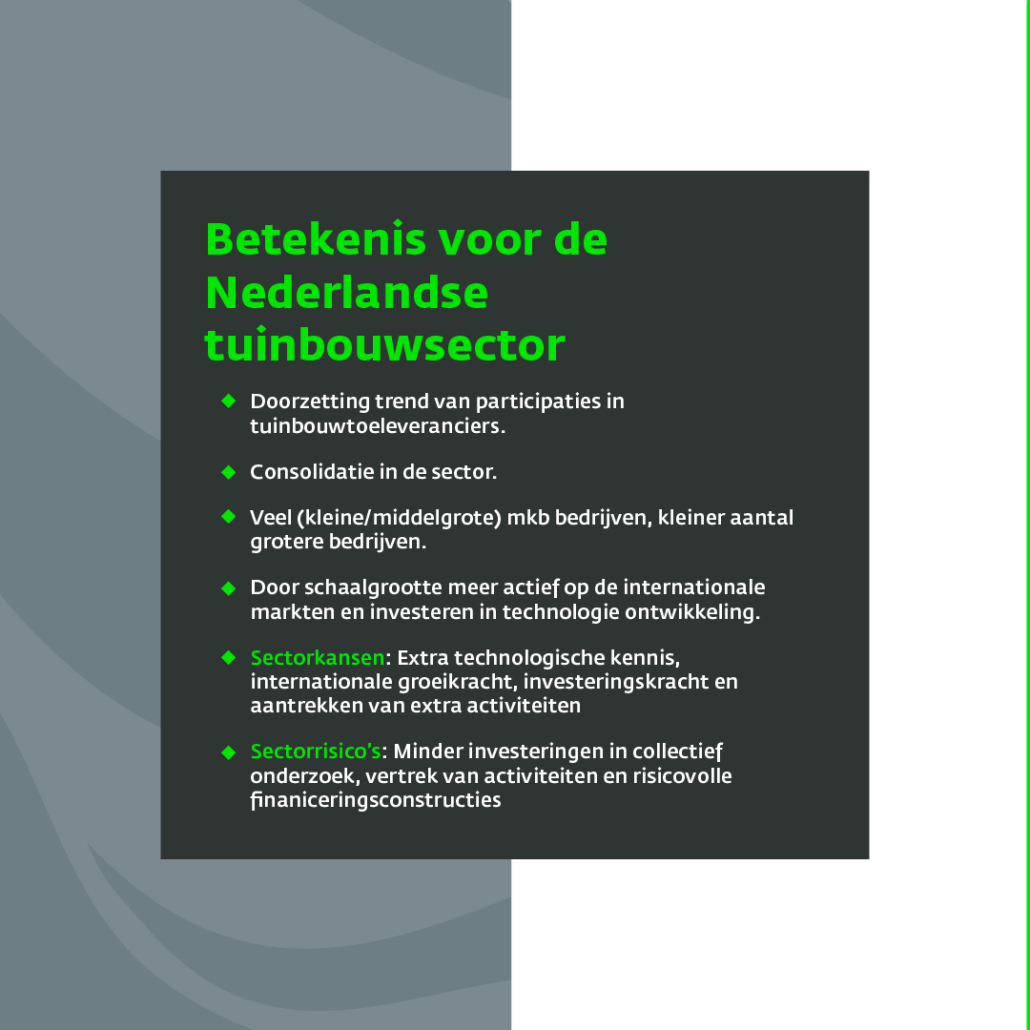

For the sector as a whole, the quick scan advises embracing the benefits of foreign capital participation without losing sight of the importance of a vibrant Dutch horticultural sector. This involves keeping a close eye on Dutch businesses with international shareholders while encouraging foreign companies to play an active role in the ecosystem.